Please note our new address is now 91 Belmont Avenue Belmont Western Australia 6104.

- (08) 9355 3588

- sales@taman.com.au

- Australia-wide Delivery

Please note our new address is now 91 Belmont Avenue Belmont Western Australia 6104.

From construction and manufacturing to mining and geological exploration, the demand for clean, precise and efficient hole creation has driven significant advancements in drilling technologies.

Among these innovations, the diamond core drill bit has emerged as a transformative force, offering unparalleled precision, speed and versatility.

As experts in precision core drill bits throughout Australia, we are well qualified to delve into the significance of the diamond core drill bit in achieving precision drilling outcomes, while emphasising the importance of proper selection, maintenance and safety practices.

The diamond core drill bit revolutionised precision drilling with its diamond-embedded design, offering unparalleled accuracy, speed and versatility. From construction to manufacturing and mining, they enhance efficiency and productivity while ensuring clean, precise holes with minimal effort and downtime.

In our experience, accuracy and quality have become paramount, in turn offering unrivalled advantages. The correct choice of drilling equipment plays a pivotal role in determining the success of diverse projects.

At the heart of the diamond core drill bit lies a sophisticated design that incorporates industrial-grade diamonds embedded within a metal matrix.

One reason we specialise in diamond core drill bits is that, unlike conventional drill bits which rely on friction and force to penetrate surfaces, diamond core drill bits harness the supreme hardness and durability of diamonds to cut through materials with remarkable precision and efficiency.

For us, this unique design ensures that the cutting edges remain sharp and intact, resulting in clean, uniform holes without burrs or irregularities.

The adoption of diamond core drill bits brings with it a multitude of advantages that elevate drilling operations to new heights:

Diamond core drill bits excel in creating clean, accurate holes with smooth edges, making them indispensable for applications where precision is paramount.

Whether it’s installing plumbing fixtures in construction projects or extracting core samples in geological exploration, to our clients, the ability to achieve precise hole placement is essential for achieving the desired outcomes.

A diamond core drill bit offers remarkable speed and efficiency, significantly reducing drilling time and enhancing productivity.

Of course, the exceptional cutting ability of diamonds enables these drill bits to penetrate even the hardest materials with ease, resulting in faster completion of drilling tasks and reduced labour costs.

For us, one of the standout features of diamond core drill bits is their versatility in cutting through various materials, including concrete, stone, glass and ceramics.

This versatility makes them invaluable tools for contractors, engineers and DIY enthusiasts alike, allowing for seamless drilling operations across a wide range of applications and industries.

As we know in the industry, diamond core drill bits are renowned for their exceptional durability and longevity.

Unlike conventional drill bits, which may wear out or become dull over time, our diamond core drill bits retain their cutting effectiveness over an extended period.

This results in consistent drilling performance, reduced maintenance requirements and reduced costs.

The versatility and precision of diamond core drill bits find applications across a multitude of industries:

In the construction industry particularly, a diamond core drill bit is used for creating precise openings in concrete, brick and masonry walls.

Whether it’s installing plumbing fixtures, electrical conduits or HVAC ducts, diamond core drill bits ensure accurate hole placement and clean edges, creating an awesome finish, as well as minimising the need for patching or repair work.

In mining and geological exploration, diamond core drill bits are essential tools for extracting core samples from rock formations.

These samples provide valuable insights into the composition and structure of the earth’s crust, helping geologists and engineers assess mineral deposits, groundwater resources and geological hazards.

In manufacturing facilities, diamond core drill bits are used for precision drilling in the production of electronic components, machinery parts and automotive components.

Indeed, whether it’s creating holes for fasteners, bearings or sensors, diamond core drill bits offer unmatched accuracy and efficiency, helping our clients produce high-quality finished products.

Even the diamond core drill bit industry is moving forward and recent advancements in their manufacturing process have further enhanced their performance and efficiency:

Manufacturers are always developing new diamond coatings and formulations to improve cutting performance and durability within our range of diamond drill bits.

These advanced coatings enhance the abrasion resistance and thermal conductivity of the drill bits, resulting in longer tool life and improved drilling efficiency.

We keep up with industry insights, so we know that researchers are exploring novel cutting geometries and designs to optimise the drilling process and minimise tool wear.

By incorporating features such as helical flutes, stepped profiles and multi-stage cutting edges, diamond core drill bits can achieve smoother, more efficient drilling performances across a wide range of materials and applications.

The integration of smart technologies, such as sensors and real-time monitoring systems, is revolutionising the way diamond core drill bits are used and maintained.

These smart drill bits can provide valuable data about drilling parameters, tool conditions and performance metrics, enabling operators to optimise drilling processes and prevent costly downtime.

When selecting a diamond core drill bit for a specific application, several factors should be considered:

Different diamond core drill bits are designed to cut specific materials, ranging from softwoods and plastics to hardened steel and reinforced concrete.

With this in mind then, it is essential to select a drill bit with the appropriate diamond grit and bonding matrix for the material being drilled to achieve optimal cutting performance and tool life.

The size of the drill bit should match the desired hole diameter and depth, taking into account any tolerance requirements or dimensional constraints.

Oversized or undersized drill bits may result in inaccuracies or surface defects, so it’s crucial to choose the right size for the job at hand.

We carry a wide range of drill bits from 12mm to 600mm. We can also custom-make drill bits in almost any length and diameter. So, for all your core drill bit needs, simply contact us.

Diamond core drill bits are available in various configurations, including wet and dry drilling options, as well as handheld and stationary models.

The choice of drill type depends on factors like the material being drilled, the desired hole size and the availability of water or coolant for lubrication.

It makes sense to contact us before selecting a diamond core drill bit when you have a specific application/job in mind.

We can discuss factors such as drilling speed, feed rate and cutting fluid usage (which can significantly impact drilling performance and tool life) – proper matching is crucial for achieving optimal results.

To ensure the longevity and safety of your diamond core drill bit, proper maintenance and safety practices should be followed:

Regular inspection and cleaning of diamond core drill bits are essential to remove debris, lubricants and other contaminants that can affect cutting performance.

Additionally, sharpening or reconditioning may be necessary to restore worn or damaged cutting edges, again prolonging tool life. It is worth noting that, in addition to our range of core drill bits, we also carry a range of spares for the equipment we sell.

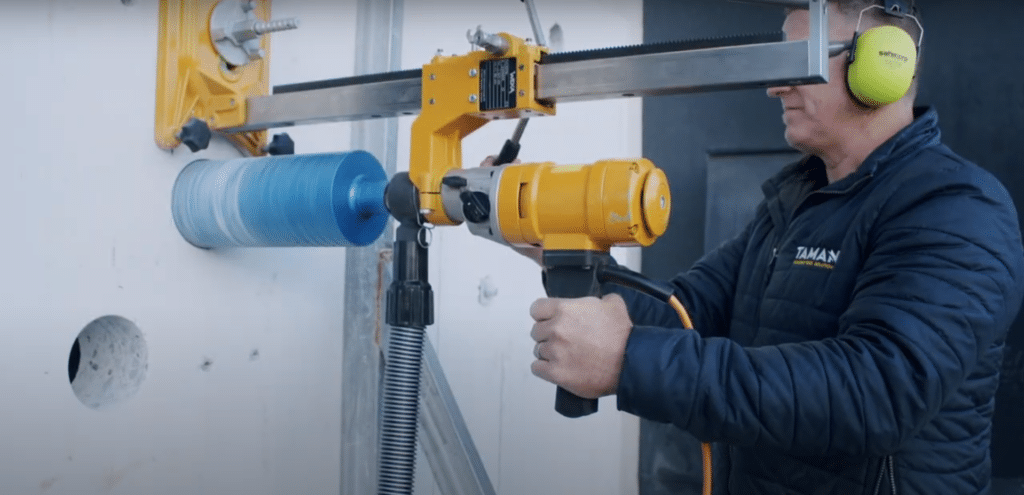

Safety is paramount and we all know that when using diamond core drill bits, it’s vital to wear appropriate personal protective equipment (PPE), including safety glasses, gloves and hearing protection.

Proper ventilation and dust control measures should also be implemented to minimise exposure to airborne particles and contaminants.

Additionally, operators should follow recommended operating procedures and adhere to all safety guidelines provided by the drill bit manufacturer.

The diamond core drill bit has undoubtedly revolutionised precision drilling across various industries, offering unmatched accuracy, efficiency and versatility.

By selecting the right drill bit for the job and adhering to proper maintenance and safety practices, users can maximise the benefits of diamond core drill bits while minimising risks and ensuring optimal performance.

Wherever you are in Australia, for your diamond core drill bit needs or any core drill bit needs, simply contact us,Taman Diamond Tools, – we’ll be happy to assist you!

ABN 31 008 817 570

Fill in your details below and we’ll call you back as soon as we can.